Product Information

Content

|

1. General Information 2. Adhesive Mechanism 3. Adhesive strength 4. Bonding method |

|

|

|

|

| 1. General Information |

|

Cerasolzer is used in manufacture of electrical parts, to contact

electrical / electronically materials and flat glass / metalized

glasses because it provides a unique bonding technique that can take

the place of commonly used bonding methods like silver baking, indium soldering,

molybdenum-manganese and resin (flux).

With conventional soldering methods, glass, ceramic, aluminum and stainless

steel are commonly known as

non-solderable materials.

This is because 'heat' is not enough to bond/solder such substrates

and metal oxides.

Ultrasonic vibrations in conjunction with heat cause the required

effect and delivers the technical break through. This principle is based on the scientifically recognized

'Ultrasonic Cavitational Phenomenon' which is caused by strong

ultrasonic penetration.

The Cerasolzer active-solder alloy together with an ultrasonic

activated soldering system enables to solder on ‘hard-to-solder’

materials flux free

|

|

|

| 2. Adhesive Mechanism |

|

Although it is quite difficult to completely explain the mechanism of how

Cerasolzer adheres to materials, these mechanisms are qualitatively understood as follows:

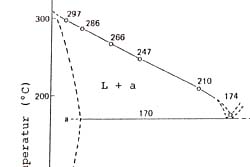

Since the adhesive property of Cerasolzer is essentially based upon the characteristics

of the alloy, ultrasonic vibration is applied to help its

bonding process. Cerasolzer contains little amount of elements like Zn, Ti, Si, Al, Be, and Rare Earth which have a strong

chemical affinity with oxygen. these metals are thought, during the

bonding process, to combine with the oxygen in air to form oxide, which

is chemically bound to the surface of the glass, ceramics, metal

oxide, etc. Thus, Cerasolzer bonding process proceeds under the

liquid-solid reaction between oxides themselves. Such adhesive

mechanism has been already confirmed in other areas of glass-metal

bonding such as vacuum tube sealing.

Accordingly, if oxygen is competely eliminated by substituting the air surrounding

the bonding equipment with an inactive gas, e.g., nitrogen, the

adhesion of Cerasolzer will be lost. It has been experimentally

found that the critical oxigen concentration for adhesion is

about 2%.

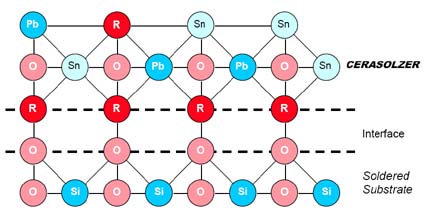

A model of chemical bonding between Cerasolzer and the substrate is illustrated in Fig. 15.

Fig. 15 Adhesive mechanism of

Cerasolzer

Fig. 15 Adhesive mechanism of

Cerasolzer

When quartz glass is used, the metallic oxides (RO), which are components of

Cerasolzer unite chemically with the SiO2

(M) of glass.

|

|

|

| 3. Adhesive Strength |

|

|

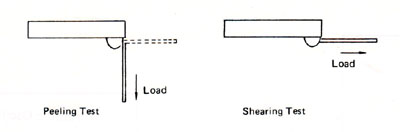

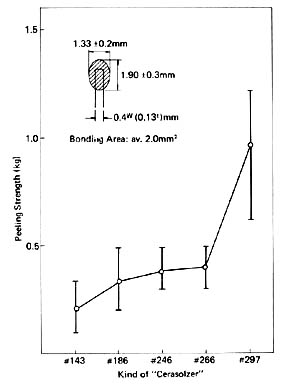

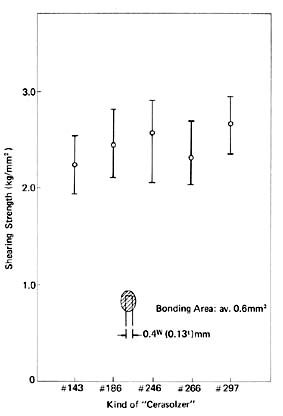

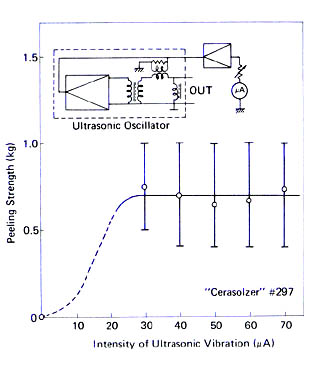

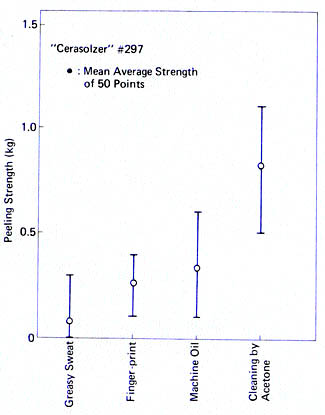

Since Cerasolzer has a number of applications, the adhesive strength of Cerasolzer must be measured by the application. Here, the adhesive strength is described for the lead bonding to soda glass or In2O3 - coated glass performed by the one-step method. Physical and chemical factors should be noticed that particularly affect the bonding performance of Cerasolzer. |

|

| Method of adhesive strength measurement: |

|

|

|

|

| Figure 5 Peeling strength of each kind of Cerasolzer Top |

|

|

|

|

| Figure 6 Shearing strength of each kind of Cerasolzer Top |

|

|

Figure 7 Effect of intensity of ultrasonic vibration on peeling strength Top |

|

|

|

|

|

Figure 8 Influence of contamination of glass surface on peeling strength Top |

|

|

|

|

|

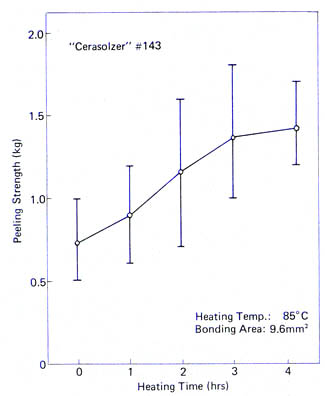

Figure 9 Effect of aging on peeling strength Top |

|

|

|

|

|

Figure 10 Temperature aging test Top |

|

|

|

|

|

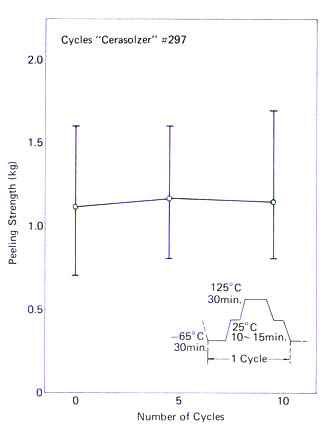

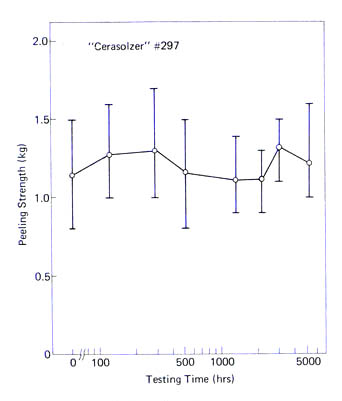

Figure 11 Life test (at 125°C) Top |

|

|

|

|

|

Figure 12 Humidity test (at 40 ± 3°C, 90 - 95 %RH) Top |

|

|

|

|

|

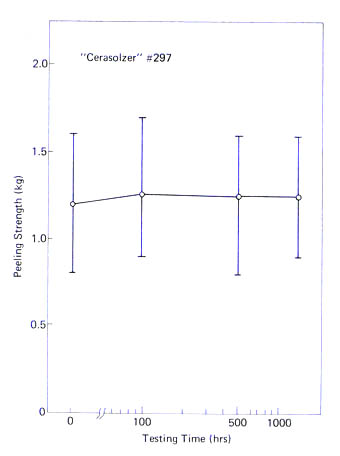

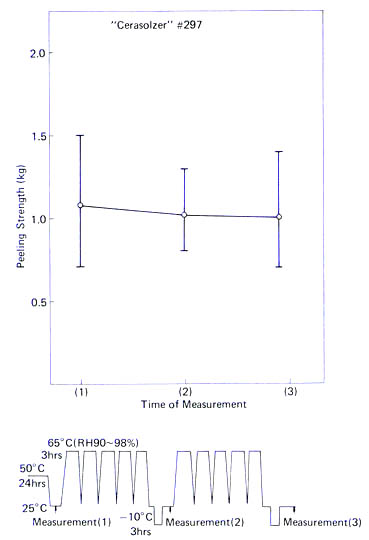

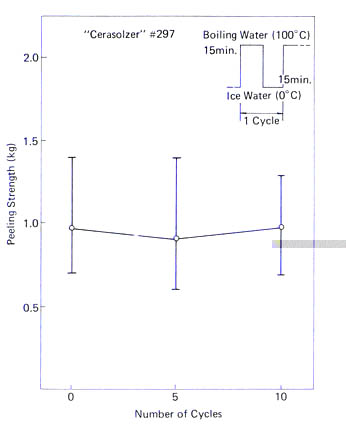

Figure 13 Moisture resistance test Top |

|

|

|

|

|

Figure 14 Thermal shock test |

|

When coating glass,

ceramics and metal oxide with Cerasolzer, it is necessary to keep

complete contact between Cerasolzer and the substrate by employing

friction, to eliminate small bubbles which existing in the

boundary zone between the surface of the substrate and the molten

Cerasolzer.

Practically, this requirenment is most effectively satisfied by

applying ultrasonic vibration. For example, upon application of the

method to the molten Cerasolzer coated on a transparent glass plate,

complete contact between Cerasolzer and the substrate is established

to make the boundary zone look like the so-called 'mirror-surface'.

Ultrasonic/Cerasolzer bonding can be performed by three methods:

1. Two-Step Method

Cerasolzer is fed to

the nose of a specially made ultrasonic tip and coated on glass,

ceramics or metal oxide. Then the metal fittings, lead wire, etc. are

soldered on the surface of the Cerasolzer using ordinary solder.

This method is convenient to make an airtight seal and to attach

large sized metal fittings, lead wire, etc.

2. One-Step Method

While Cerasolzer is

sandwiched in a slit between metal and glass or ceramics or metal

oxide, ultrasonic vibration is applied directly to the metal. Bonding

is performed whithin a very short time. This method is quite

adequate for lead bonding on a display panel or on a resistor

element.

3. Dipping Method

Cerasolzer is melted in

a specific crucible which is equipped with an ultrasonic vibrator.

While the molten Cerasolzer has a ripple on its surface caused by

ultrasonic vibration, the specimen is dipped in. This method is of

good use for whole surface coating with Cerasolzer.

IMPORTANT

The most important in bonding with Cerasolzer is the surface

cleanliness of the substrate - glass, ceramics, metal oxide etc.

Such cleanliness does significantly affect the bonding performance of

Cerasolzer. In particular, staining with organic substrate (resin,

finger-prints, flux for ordinary solder), acid, alkali, powder,

carbon, etc must be absolutely avoided. Best cleaning results are

achieved by using 'chemically clean' Acetone.